Interview : Our Virtual Try-on project for Baume & Mercier Riviera watch

By |Table of contents

Founded in 1830, Baume & Mercier perpetuates the excellence of Swiss watchmaking with its 190 years of know-how. The brand has created a place of choice in the market by offering its consumers elaborate designs and by putting timelessness and creativity at the center of their values.

The Riviera watch :

The Baume & Mercier Riviera is a watch first presented in 1973. This year, the House presents the renewal of this collection. A hallmark of an era, this model is available in several configurations with an assertive style. For the new release of this emblematic watch, the House has trusted us to create with them a virtual try-on experience online, proving once again, even in the customer experience, that this watch has been able to reinvent itself to fit the codes of its time. To find out more about this project, we interviewed 2 of our Hapticmedia experts who participated in it : Olivier Sudermannn, 3D graphic designer and Pierre Chanteloup AR/VR Engineer.

Pierre Chanteloup, AR/VR Engineer

Olivier Sudermann, 3D graphic designer

What was the mission ?

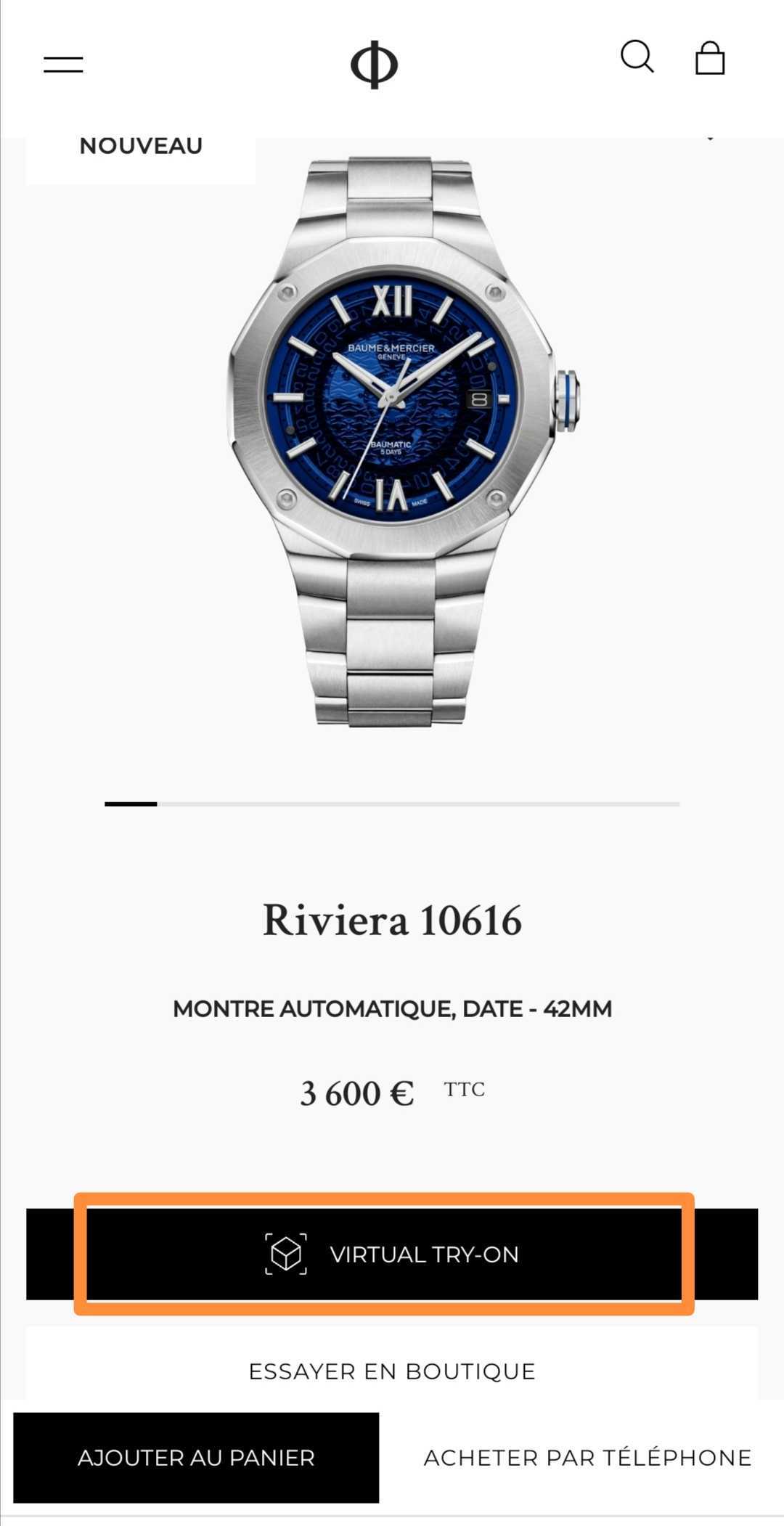

The initial mission was to allow the brand to offer its online customers a virtual try-on of the Riviera watch in real time. The goal was to visualize the product page and then to see how it would look on the wrist virtually.

It was important for the brand that the visuals be realistic and in the image of the real product, but also that the experience be fluid, practical and easy. That’s why the experience is available to everyone, without any mobile application, directly in the browser.

With who did you worked ?

Olivier : Internally, 3 departments were mobilized:

- The rendering and modeling unit (of which I am a member)

- Our R&D department, of which Pierre is a part

- And the technical & integration unit.

Being part of the rendering & modeling department, I intervened on the project as a watchmaking expert, on the parts of modeling, materials, rendering, lighting … etc. Pierre, who is part of the research team, worked with his R&D team on the virtual try-on experience.

We also collaborated with Baume & Mercier’s technical and product teams in order to gather their needs, understand their artistic vision and become immersed in their brand image, then in a second phase for the integration.

What were the major steps of the project ?

1/ Modeling

Olivier: From the CAD models sent by the brand, We were able to start the modeling. Using photos of the watches, we worked on the shapes and reliefs of this emblematic watch. we had to model 3 sizes of watches (36, 42 and 43mm). The first one available in 5 variations, the second one in 7 variations, and the last one in 3 variations.

The particularity of this project was to make a model and a rendering adapted to a Virtual try-on experience and not to a 3D configurator. Thus, it was important to take into account the shape and size of the wrist as well as the rendering on camera.

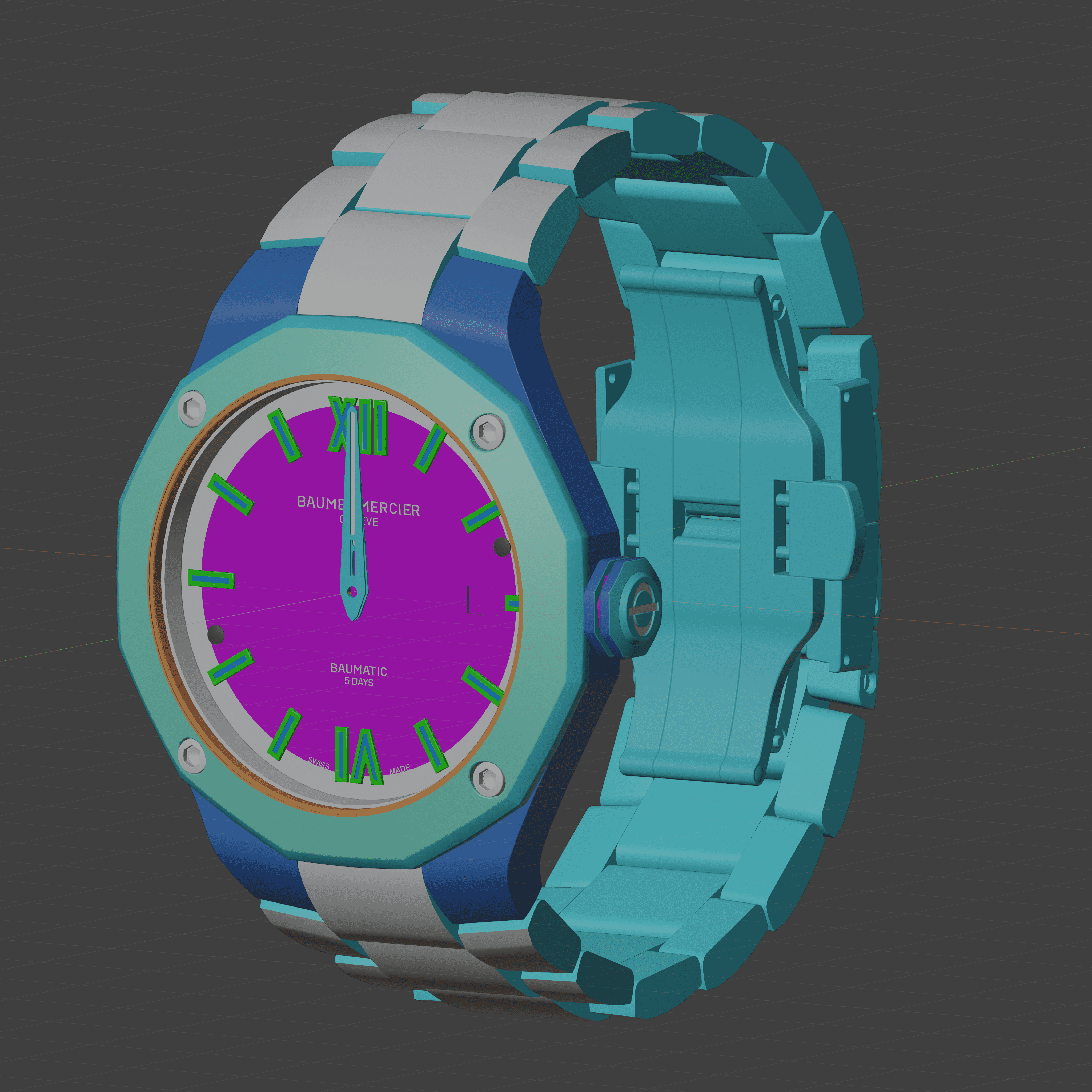

Image : Draft of the watch during modeling stage

2/ Rendering set ups

Olivier : We applied the specific materials on the watch models: metal and rubber applied on the strap, and a custom creation for the dial, since it is a solarized dial, which on certains variations is transparent in order to reveal the watch mechanism.. Indeed, it is necessary to create this tailor-made material, in order to replicate the effects of transparency and light of the real object as faithfully as possible.

For the lighting, we had to find a compromise. An initial lighting had been defined for the watch in soldier view, but for the virtual try-on experience, another lighting was needed to highlight the rendering of the watch on the wrist. The goal was to find the right compromise in order to obtain a rendering that would be as natural as possible on the wrist, while respecting the artistic direction and the visual identity of the brand.

Finally, we added the last details to bring more realism to the experience, such as the shadows on the watch around the wrist, for example.

Image : Draft of the watch during reendering set up stage

The last step of my part was to optimize the weight of the 3D model so that it is as light as possible to ensure a smooth and latency-free virtual try-on experience.

3/ Virtual Try-on experience creation

A research & innovation process

Pierre : The main feature is that this is a first. For us and for them.

In this sense, we are part of a true innovation process. Throughout its years of expertise, Baume & Mercier has been able to reinvent itself and even position itself as a forerunner on the market. Our collaboration on this project is part of the same dynamic and creates a world first in the watchmaking world, an interactive virtual try-on experience in real time and in the browser (without mobile application).

Formulation of the client’s needs

Pierre : To start the project we first collect the client’s needs. To understand not only his expectations but also his restrictions. We also specify this need in order to elaborate a defined planning.

User needs analysis

Pierre : The collecting of customer needs results in the study of user needs. The end users of the virtual watch try-on. This is to understand what their behaviors are, what will facilitate their experience and understanding. The way they instinctively position their arm during the fitting, the hand on which they would try the watch, the angle of view from which they film themselves etc.

Instagram post on the brand account

Preliminary experiments

Pierre : We then conduct tests on the selected hypotheses in order to validate or invalidate certain leads. We explore several axes in order to determine which one(s) to pursue. To select the right track to explore, we choose the solution that appears to be the most feasible, qualitative and optimal.

Generating and collecting data

Pierre : Once this is established, the goal is to generate and collect data in order to start a machine learning process. Here, we give the machine as many cases as possible so that it can recognize them when they occur and know where to position the watch even when the user makes movements. So we feed the algorithm several images with different conditions that are meant to be representative of the variety of user behaviors.

Image : Riviera campain photo posted on Baume & Mercier instagram, with @lukas_hof

Iteration and optimization

Pierre : Then we analyze how the algorithm reacts and if it reacts well, we detect the problems to correct them and repeat the operation. This is where the iteration process begins in order to obtain each time an improved version that treats a greater variety of cases, or that is more qualitative.

Implementing the module

Pierre : Finally, when we have reached a result that is operational and suitable for the client, we implement the product model and then integrate the complete experience on the client’s website.

What did you appreciate about this project ?

Olivier:

First of all, I enjoyed working for an emblematic house on an iconic watch. Then, in general, what I enjoyed the most was taking up the challenge of innovation. To adapt an artistic vision to a completely new and different environment and to go a little further in the possibilities of customer interaction. The compromise that had to be found on the lighting is a perfect example. I also liked to provide a “turnkey” solution since it can be directly integrated on the product pages of the client’s website, you just have to add a “try the watch” button and the solution works directly in the browser.

Image : Screenshot of the Riviera watch product page on mobile, with the virtual try-on implemented

Pierre:

For my part, what I appreciated most about this project was being in an innovative and pure R&D approach. First of all, the initial objective was super stimulating: to participate in a world first, to do virtual try-on in real time on a timepiece.

We had already done a virtual try-on experience before, but with markers, and to be able to do it without markers really gives me a sense of accomplishment.

Secondly, I particularly enjoyed working in project mode. To follow from A to Z and see the result is quite rewarding.

Finally, what I appreciate most is the opportunities that it brings. Having succeeded in doing a virtual try-on without markers for this product opens up many horizons for other fields of application and other products.

Contact Hapticmedia now to see our successful user cases and the visible improvement we have brought to our clients. You will be amazed.